In the intricate world of material science and industrial manufacturing, the quest for enhancement is never-ending. Engineers and formulators are perpetually seeking solutions to make materials stronger, more durable, more efficient, and more reliable. This pursuit often leads to the development of advanced additives—specialized compounds that, when integrated into a base material, impart specific, superior properties. One term that has emerged in certain technical and industrial circles, symbolizing this cutting-edge innovation, is NovaPG.

While “NovaPG” is not a universal standardized chemical name you would find on a periodic table, it is best understood as a conceptual or brand-oriented term for a novel class of performance-grade additives. The name itself offers clues: “Nova,” from the Latin for “new,” suggests innovation and a leap forward, while “PG” most commonly denotes “Performance Grade” or “Polymer Grade.” This positions NovaPG not as a single substance, but as a hallmark of a advanced additive technology designed to elevate material performance to a new tier.

Table of Contents

The Core Concept: What is NovaPG?

At its heart, NovaPG represents a paradigm shift in additive technology. Traditional additives often address a single property, such as a UV stabilizer to prevent sun degradation or a plasticizer to increase flexibility. NovaPG-based solutions, however, are engineered with a multifunctional approach. They are designed to be synergistic systems that can simultaneously enhance several key properties of a host material, primarily polymers, composites, and synthetic lubricants.

The philosophy behind such technology is integration over addition. Instead of loading a material with five different single-function additives that might interact poorly or add excessive weight and cost, a NovaPG additive package aims to deliver multiple benefits through a single, sophisticated formulation. This could involve:

- Enhanced Thermal Stability: Preventing polymer degradation at high operating temperatures.

- Superior Mechanical Strength: Increasing tensile strength, impact resistance, and reducing wear.

- Improved Tribological Properties: Reducing friction and minimizing energy loss in moving parts.

- Oxidative and Corrosion Resistance: Protecting against breakdown from exposure to oxygen, moisture, and chemicals.

Potential Applications Across Industries

The value of a multifunctional, high-performance additive is immense and spans numerous sectors.

1. Automotive and Aerospace:

In these industries, weight reduction is directly tied to fuel efficiency and performance. NovaPG-type additives could be integrated into polymer composites used for interior panels, under-the-hood components, and even structural elements. By increasing the strength-to-weight ratio and heat resistance of these materials, manufacturers can create lighter, more efficient, and more durable vehicles and aircraft without compromising safety.

2. Industrial Manufacturing and Machinery:

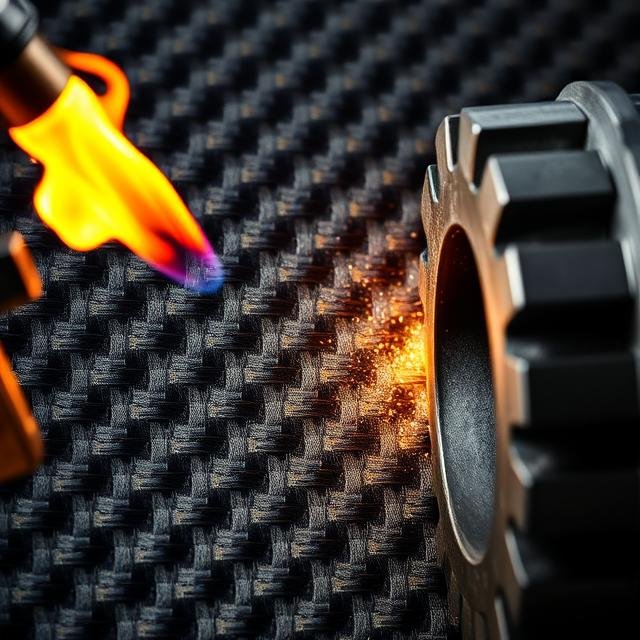

Gears, bearings, seals, and guides are constantly subjected to friction and wear. Incorporating NovaPG additives into the engineering plastics or composite materials used for these parts could drastically extend their service life, reduce downtime for maintenance, and improve the overall energy efficiency of machinery by lowering the coefficient of friction.

3. Renewable Energy:

The wind energy sector, in particular, relies on massive composite blades for turbines. These blades must withstand extreme environmental stress, including UV radiation, temperature fluctuations, and physical fatigue. An additive package that enhances UV resistance, structural integrity, and fatigue life simultaneously would be invaluable for increasing the longevity and reliability of renewable energy infrastructure.

4. High-End Consumer Goods and Electronics:

For products where premium feel and durability are key selling points—such as high-performance sports equipment, durable electronic casings, and wearables—NovaPG technology could provide the enhanced material properties that differentiate a product in a competitive market. Think of a smartphone case that is incredibly thin and light yet nearly impervious to scratches and drops, or a bicycle frame that is lighter and stronger than traditional carbon fiber.

The Science Behind the Performance

The efficacy of an advanced additive like NovaPG likely hinges on its foundational components and the technology behind its integration. While specific formulations are proprietary, they often involve nanotechnology or advanced chemical engineering.

- Nanoscale Reinforcement: Many high-performance additives utilize nanoparticles (e.g., graphene, carbon nanotubes, or specialized ceramic nanoparticles). Their incredibly high surface area-to-volume ratio allows them to interact with the host polymer matrix on a fundamental level, providing exceptional reinforcement without adding significant bulk.

- Surface Functionalization: The true challenge is ensuring these nanoscale particles disperse evenly throughout the material without clumping together (agglomeration). NovaPG technology would undoubtedly involve sophisticated chemical treatment of particle surfaces to ensure perfect compatibility and uniform distribution within the polymer, which is critical for achieving consistent, predictable performance.

- Synergistic Formulations: It’s not just about one miracle particle. The “PG” (Performance Grade) suggests a carefully balanced blend of various agents—stabilizers, lubricants, strengthening agents—that work in concert, each amplifying the effects of the others rather than interfering.

Challenges and Considerations

Adopting any new advanced material technology comes with hurdles. For a product like NovaPG, these might include:

- Cost: Developing and producing such sophisticated additives is inherently expensive, which could initially limit their use to high-value, performance-critical applications.

- Processing Compatibility: The additive must be easily incorporated into existing manufacturing processes (e.g., injection molding, extrusion) without requiring major retooling or causing processing difficulties.

- Long-Term Testing and Certification: Especially in regulated industries like aerospace and automotive, new materials must undergo rigorous long-term testing to prove their reliability and safety over the entire lifespan of a product.

Conclusion: The Future is Additive

NovaPG serves as a powerful symbol of the next wave of innovation in material science. It moves beyond the concept of simple additives to a more holistic, system-based approach to material enhancement. By offering a multifunctional solution that boosts strength, durability, and efficiency simultaneously, technologies under the NovaPG banner have the potential to revolutionize how we design and manufacture products across a vast spectrum of industries. As research continues and these technologies become more accessible, we can expect to see stronger, lighter, and longer-lasting materials becoming the new standard, quietly powered by the next generation of performance-grade additives.

Informational FAQs About NovaPG

Q1: Is NovaPG a specific chemical I can buy?

A1: No, NovaPG is not a standardized chemical name like polyethylene or titanium dioxide. It is a conceptual or brand-derived term that represents a class of advanced, multifunctional performance-grade additives. You would need to contact specific chemical companies to inquire about products that fall under this technological category.

Q2: What industries would benefit most from NovaPG technology?

A2: Industries that prioritize material performance, weight reduction, and durability stand to benefit the most. This includes aerospace, automotive manufacturing, renewable energy (especially wind turbine production), high-end consumer goods, and industrial machinery.

Q3: Are NovaPG additives safe and environmentally friendly?

A3: The safety and environmental impact of any chemical additive depend entirely on its specific formulation. Any reputable manufacturer would provide Safety Data Sheets (SDS) for their products, detailing handling procedures, potential hazards, and environmental information. As with any new technology, a full lifecycle analysis is necessary to understand its complete ecological footprint.

Q4: How are NovaPG-type additives integrated into materials?

A4: These additives are typically integrated during the compounding stage of material production. They are supplied as masterbatches (high-concentration pellets) or powders that are evenly blended with the base polymer resin before it is processed into its final shape through methods like injection molding or extrusion.

Q5: Can NovaPG be used in products that contact food or are used medically?

A5: This is highly dependent on the specific formulation of the additive and whether it has received the necessary approvals from regulatory bodies like the FDA (U.S. Food and Drug Administration) or EFSA (European Food Safety Authority). Not all performance additives are suitable for food-contact or medical applications.